Fibres, Yarns & Fabrics

Brief material guide for a better understanding

Our Fibres

Our Yarns

Our Fabrics

Our Fibres

Cotton

Cotton fibre is a natural fibre obtained from the seed hairs of the cotton plant. Its main component is cellulose. The seed hairs can vary in quality and length and are differentiated by what‘s called the staple length. Due to cotton‘s high moisture absorption and breathability, it offers a high

level of comfort and is durable, easy to clean, and exceptionally long-lasting.

* Cotton serves as the foundation for all our T-shirts and sweatshirts.

Viscose

Viscose is a regenerated fibre. Its main component is also cellulose. It is produced through a chemical process that dissolves wood and then spins it into endless filaments. Its properties are similar to those of cotton.

* Cotton serves as the foundation for all our T-shirts and sweatshirts.

Polyester

This is a synthetic fibre. It is produced as endless filaments from polyethylene terephthalate using a melt spinning process. During this process, fineness, sheen, and texture can be adjusted based on the intended use. Polyester is

very easy to care for and resilient. It doesn‘t absorb moisture but transports it along the surface of the fibre, which makes it well-suited for functional textiles.

* We use pure polyester in our sports and outdoor styles and also combine it with cotton fibre for increased dimensional stability in our heavy cotton products.

Polyamide

Polyamide, in specific forms named nylon, is similar to polyester in terms of production and properties. It is derived from carbon using the same process and has higher elasticity than polyester.

* You can find very fine nylon in our padded jackets and vests.

Elastane

As the name suggests, this fibre is highly stretchable. It is produced through dry spinning from polyurethane and polyethylene glycol and is usually combined with other inelastic fibres. This combination allows greater elasticity and shape retention.

* For maximum comfort in a T-shirt, we combine elastane with cotton.

Our Yarns

Filament Yarns

When synthetic fibres are used in their endless length instead of being cut into short pieces, they are referred to as filament yarns. In clothing, they are often used as multifilament yarns, which are yarns composed of numerous very fine filaments. The yarn is produced directly in the spinning process, where the required number of filaments is simultaneously spun out and brought together in drafting.

The properties of the yarn can be determined by the shape, fineness, and number of filaments, surface coating, or texturing.

* For our sports styles, we use ACTIVE-DRY° polyester, a fine multifilament yarn that effectively transports moisture due to the shape of its filaments. In micro fleece, a textured, less fine yarn is used, which can be roughened on the surface to achieve the highly desired soft texture. In our outdoor jackets, the functionality of the yarns is optimally matched to their intended purpose.

Ring-spun Cotton, Carded or Combed

To create yarn from individual fibres, they are twisted together in a solid structure. In the process of ring spinning, this happens in multiple steps.

Firstly, the required amount of fibre is cleaned and oriented. This orientation can be achieved through sole carding or additional combing of the fibres. Carding roughly orients the fibres in the same direction. If particularly high yarn quality is desired, the roughly oriented fibres are then brought into high parallel alignment through combing, while simultaneously removing the shortest fibres. This results in a smoother and more durable yarn. In the next step, the oriented fibres are brought together into a sliver, a thick strand of fibres, which is then in the final step processed into a solid yarn through simultaneous stretching and rotating.

The finer the yarn is intended to be, the longer the staple length of the used fibres needs to be. Compared to other methods, the ring spinning process produces the highest yarn quality. Before the spinning process, cotton fibres can be blended with other fibres for optical or functional purposes. If the blended fibre is a regenerated or synthetic fibre, their endless filaments are cut to the staple length of cotton.

* Our cotton products are exclusively made from ring-spun cotton. In our basic wear, we use carded yarns, while in our Lux collection, combed yarns are employed.

Our Fabrics

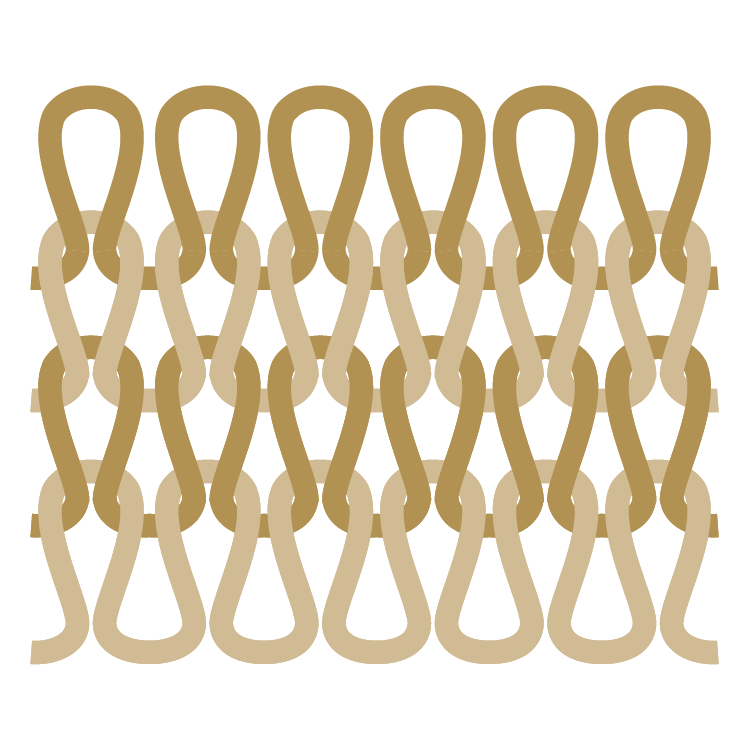

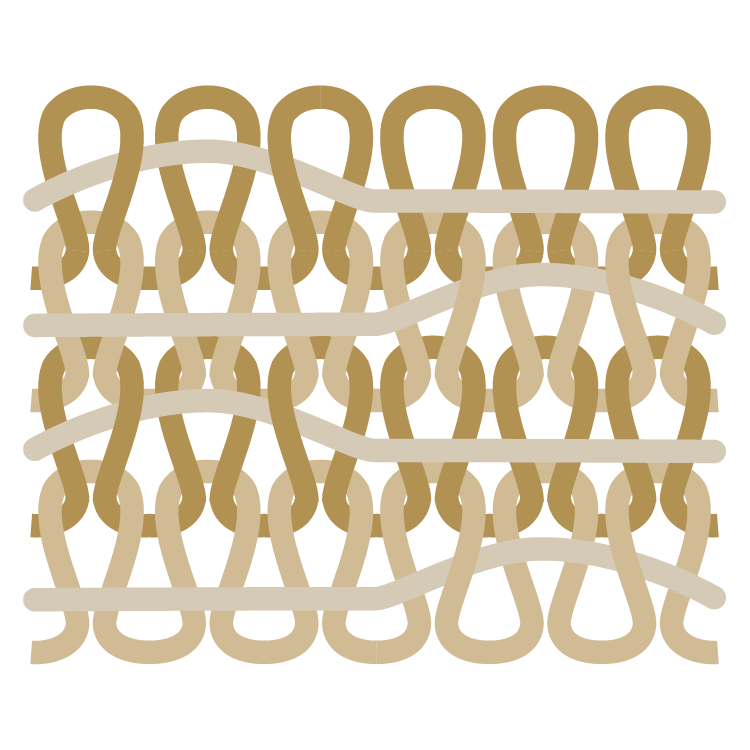

Knitted Fabrics

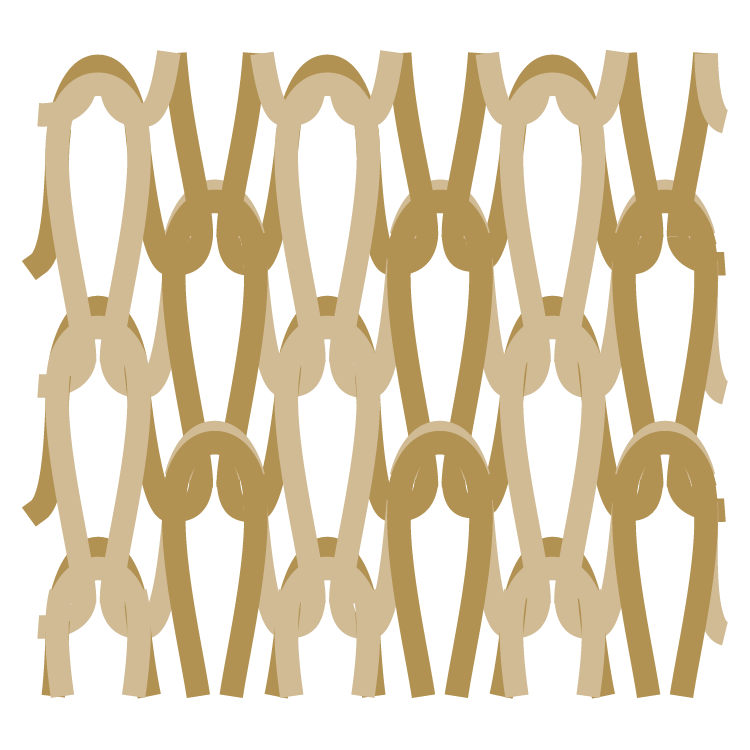

Fabrics formed by intertwining loops of thread are called knitted fabrics. The horizontally adjacent loops are referred to as courses, and the vertically adjacent ones as wales. When the thread is routed from back to front through the previous loop, it‘s called a knit stitch; when looped from front to back, it‘s called a purl stitch.

Additional design elements used in knitted fabrics are float or tuck stitches. In a float stitch, one or more loops in a course are skipped; in a tuck stitch, a loop is elongated or widened over multiple courses or wales. By combining knit and purl, tuck and float stitches, various patterns and functionalities can be achieved in the fabric. Due to their loop structure, knitted fabrics are generally very elastic and resistant to wrinkles, providing a high wearing comfort.

* The following constructions are used for our products.

Single Jersey

Single Jersey

One of the most common knitted fabrics is the single jersey. It‘s usually produced as tubular fabric on a circular knitting machine, which can create fine fabrics. On a round arrangement of needles identical stitches are knitted, resulting in two differently looking fabric sides. With only knit stitches on the right side, the fabric has a very soft and even surface that offers a pleasant feel and is great for finishing.

* All Stedman® T-shirts are made of soft single jersey, perfect for everyday wear.

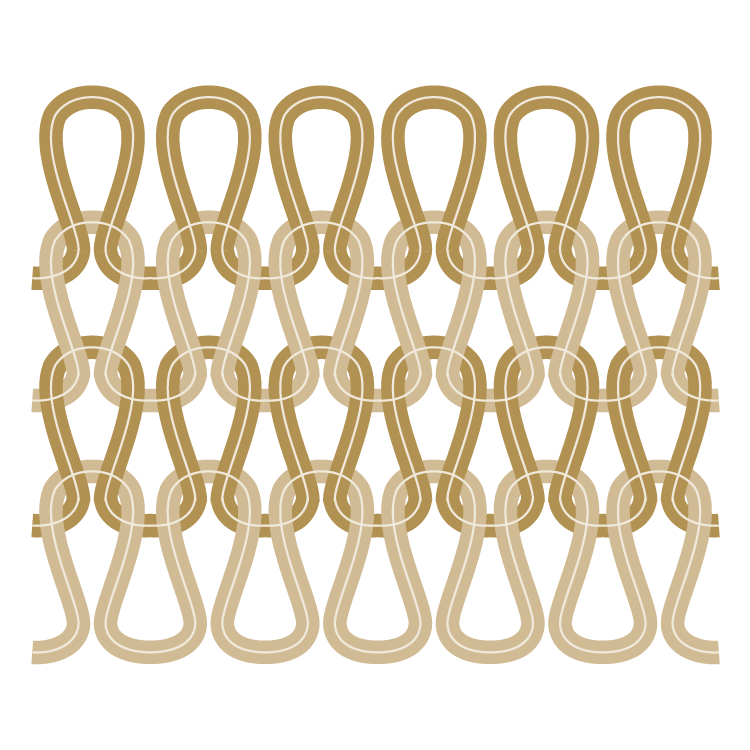

Single Jersey Full-Feeder

For added comfort and elasticity, elastane filament can be added to the knitting machine along with the cotton yarn. Depending on whether this is done in every or every second wale, it‘s referred to as “half-feeder” or “full-feeder” technology. The latter generates a more uniform distribution of elastane, thus creating a higher-quality fabric.

* Our stretch styles are made using the full-feeder technique.

Piqué

Piqué refers to fabrics with alternating raised and lowered areas on the surface, achieved through tuck stitches in knitted fabrics. Two types of piqué are used in our polo shirts:

Honeycomb Piqué

This type of piqué alternates between knit and tuck stitches in both courses and wales, resulting in a loose fabric with a honeycomb-like pattern.

* We use honeycomb piqué in our basic wear polo shirts. It is recommended for applications without significant mechanical stress.

Single Piqué

The single piqué pattern is created by repeating a sequence of four rows. It starts with a row of knit stitches, followed by a row alternating between knit and tuck stitches. The third row again consists of knit stitches only, and the last row alternates tuck and knit stitches opposite to the second row. This creates a fine but stable grid-like pattern.

* You can find single piqué in our Lux polo shirts. It is highly stable and suitable for various applications. Our stretch polo shirts are made using the same elastane filament full-feeder technique as single jersey.

Honeycomb Piqué

Single Piqué

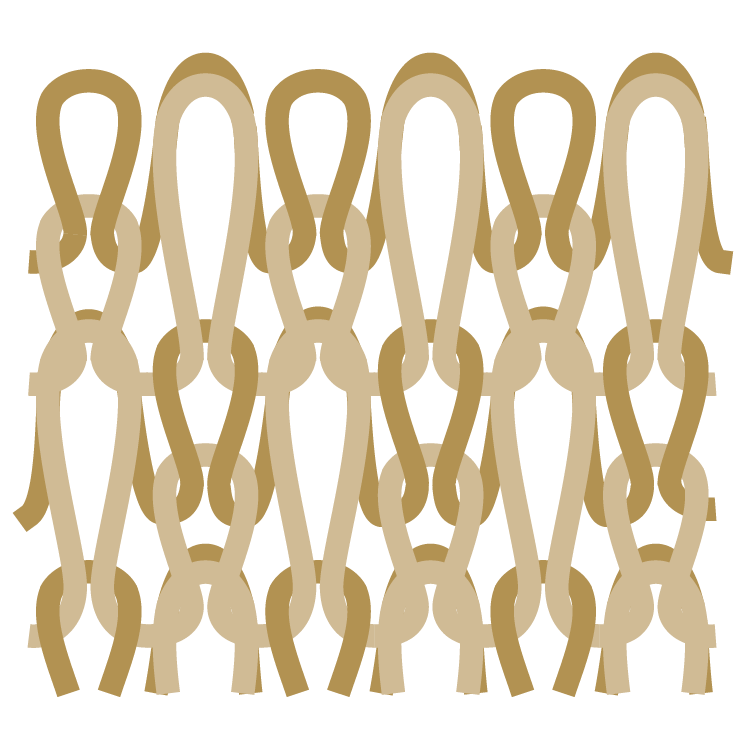

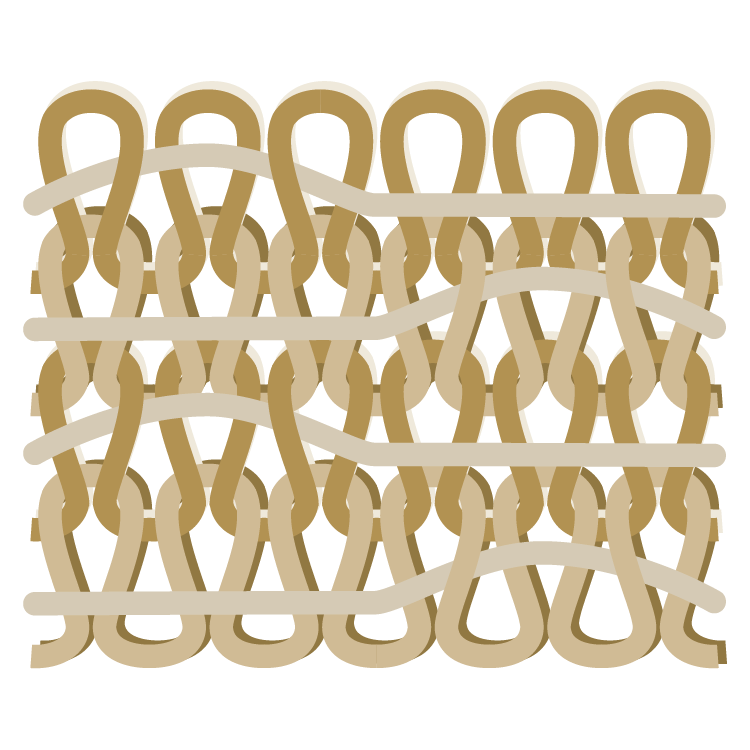

Interlock

Interlock fabrics, also known as double knits, differ from single jersey in that they are knitted on two opposing needle beds. After each stitch the yarn is transferred from one needle bed to another, creating a crossover and forming a strong bond. Knit stitches are produced on both needle beds, resulting in both fabric sides having the same appearance. Due to the stitch arrangement, interlock is slightly thicker, making it more robust than single jersey, whilst enabling various design possibilities.

* You can find pure interlock made from ACTIVE-DRY° yarn in our Sports-T’s. Its smooth surface allows for excellent finishing, while our yarn selection ensures great moisture control.

Interlock Mesh

To achieve a mesh effect, loops are elongated at regular intervals on the front needle bed of an interlock construction. This results in a perforated structure called mesh. The reverse side remains smooth as in pure interlock. The mesh structure transports moisture even more efficiently.

* We use “bird-eyelet-mesh” made from ACTIVE-DRY° yarn in our Active 140 sportswear. It is ideal for intense workouts.

Interlock

Interlock Mesh

2-Thread-Fleece

3-Thread-Fleece

2-Thread-Fleece

2-thread-fleece is a single jersey construction with a second yarn loosely attached on the backside, which is finished by brushing. These fabrics are usually lighter than their 3-end counterparts.

* You can find 100% ring-spun cotton 2-end fleece in our Light Hoodie.

3-Thread-Fleece

A 3-thread-fleece is a single jersey with two consecutive yarns and a third yarn loosely attached on the backside. This construction allows for different materials on the fabric‘s front and back sides. The left fabric side is brushed after the knitting process to achieve the characteristic soft interior.

* At Stedman® we process 3-thread-fleece from ring-spun yarns in almost all of our sweatshirts and hoodies. It utilizes pure cotton as the surface yarn, creating a soft, well-finished surface. For dimensional stability, we use a mixed yarn of cotton and polyester as the connecting yarn and weave in puffy polyester yarn on the back, which can be optimally brushed and thus generates a particularly high wearing comfort

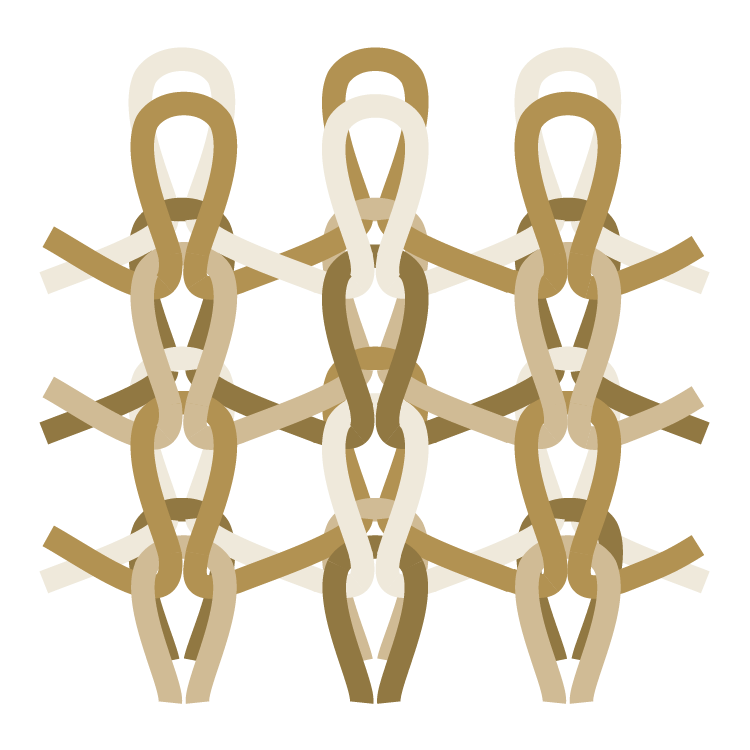

Micro Fleece

Micro fleece is created by incorporating an additional thread in a single jersey knitted fabric, forming a loop at a 90° angle to the surface. These loops are then cut open and brushed, resulting in the familiar soft surface. Depending on the desired functionality, both sides of the fabric can be brushed. Our micro fleece is made from a polyester multifilament. With a number of 144 filaments per yarn, it is referred to as a micro fibre. The soft, brushed surface not only offers a high level of wearing comfort, but can also optimally retain body heat due to the extremely high number of individual fibres on the surface of the fabric. For long-term durability, our micro fleece styles are provided with an anti-pilling finish.

Knit Fleece

The manufacturing process of our knit fleece is similar to that of a micro fleece brushed on one side and scores with the same advantages. On the right side of the fabric, however, a comparatively thick polyester multifilament creates the distinctive knit structure that gives the knit fleece its sporty, elegant look.

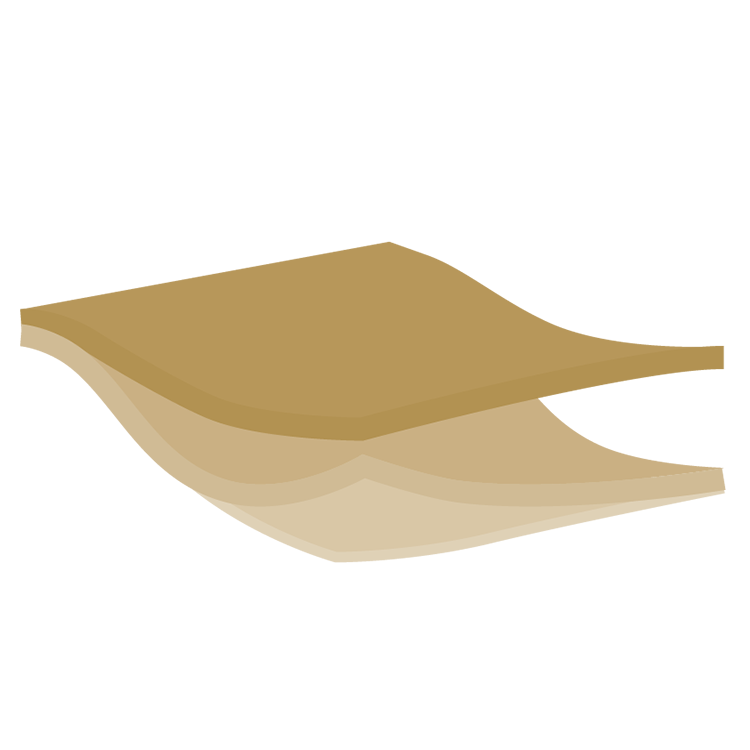

3-Layer-Softshell

A 3-layer softshell consists of three different materials that are bonded together. All three contribute to the fabric‘s functionality.

Our softshell features a fine polyester single jersey on the outside, offering elasticity and water resistance due to its choice of fibre. A semipermeable membrane is placed in the middle, preventing external water from entering while allowing body-transpired water vapor to escape. The inside of our softshell features a micro fleece, which, like the outside single jersey, is elastic and retains body heat.

Stedman® Softshell guarantees maximum comfort with optimal functionality, making it perfect for outdoor use.

3-Layer-Softshell

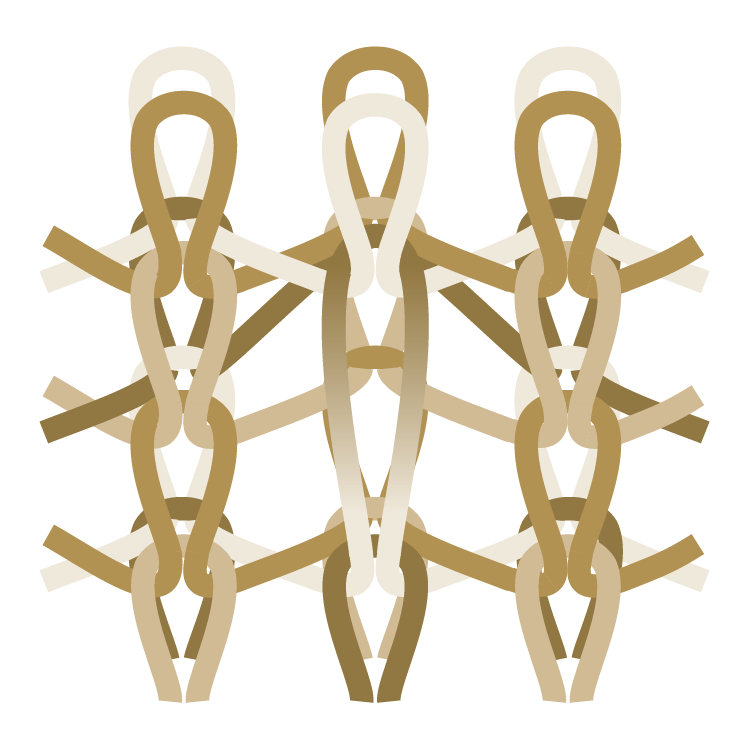

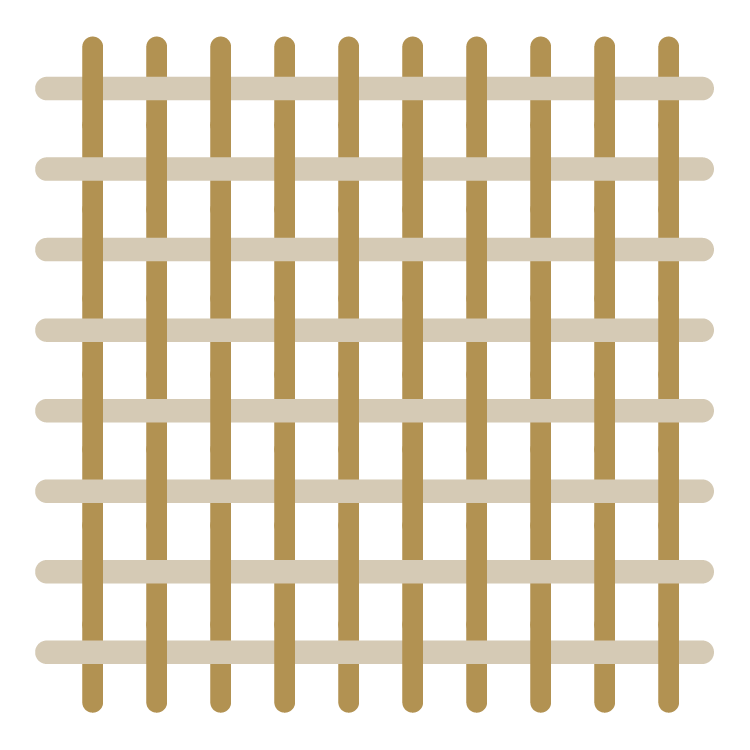

Woven Fabrics

Woven fabrics are created by crossing horizontal (weft) and vertical (warp) threads to form a textile surface. These fabrics are inherently less elastic and can be tightly woven to create waterproof surfaces. We use woven fabrics for our padded jackets and vests.

Taffeta

Taffeta is woven by using a plain weave. This is the simplest and tightest of all weave types, where each warp thread is alternating over a weft thread. Woven from water-repellent nylon, it creates a waterproof surface for our padded jackets and vests.

Tafetta